The Hard Truth About ELR

In today's competitive automotive service landscape, dealerships and service centers face mounting pressure to optimize operations, maximize revenue, and maintain customer satisfaction. But how do you address the critical challenges that plague service departments while boosting profitability and streamlining operations?

One of the most significant—and often overlooked—challenges service departments face is understanding, maintaining, and improving their Effective Labor Rate (ELR). By optimizing ELR, service departments can significantly increase profitability without sacrificing customer satisfaction. A lesser-known fact about ELR is that improvements directly enhance Labor Gross, as labor costs remain fixed, meaning every improvement flows straight to net profits.

Every Fixed Operations manager has likely experienced a General Manager's demand: "You have to get the gross up!” The usual reaction? Managers try to drive more RO traffic by sending out coupons, putting up signs, or incentivizing advisors to sell more per RO. But often, this approach is counterproductive, reducing the gross profit on existing work. This is a common vicious cycle.

Why Are You Losing ELR?

Having worked with hundreds of dealerships nationwide, I’ve found that many managers struggle to define ELR clearly, let alone explain how to influence it positively. When asked about ELR, managers often attribute it to tech. rates, advisor sales skills, or shop expenses—none of which directly impact ELR.

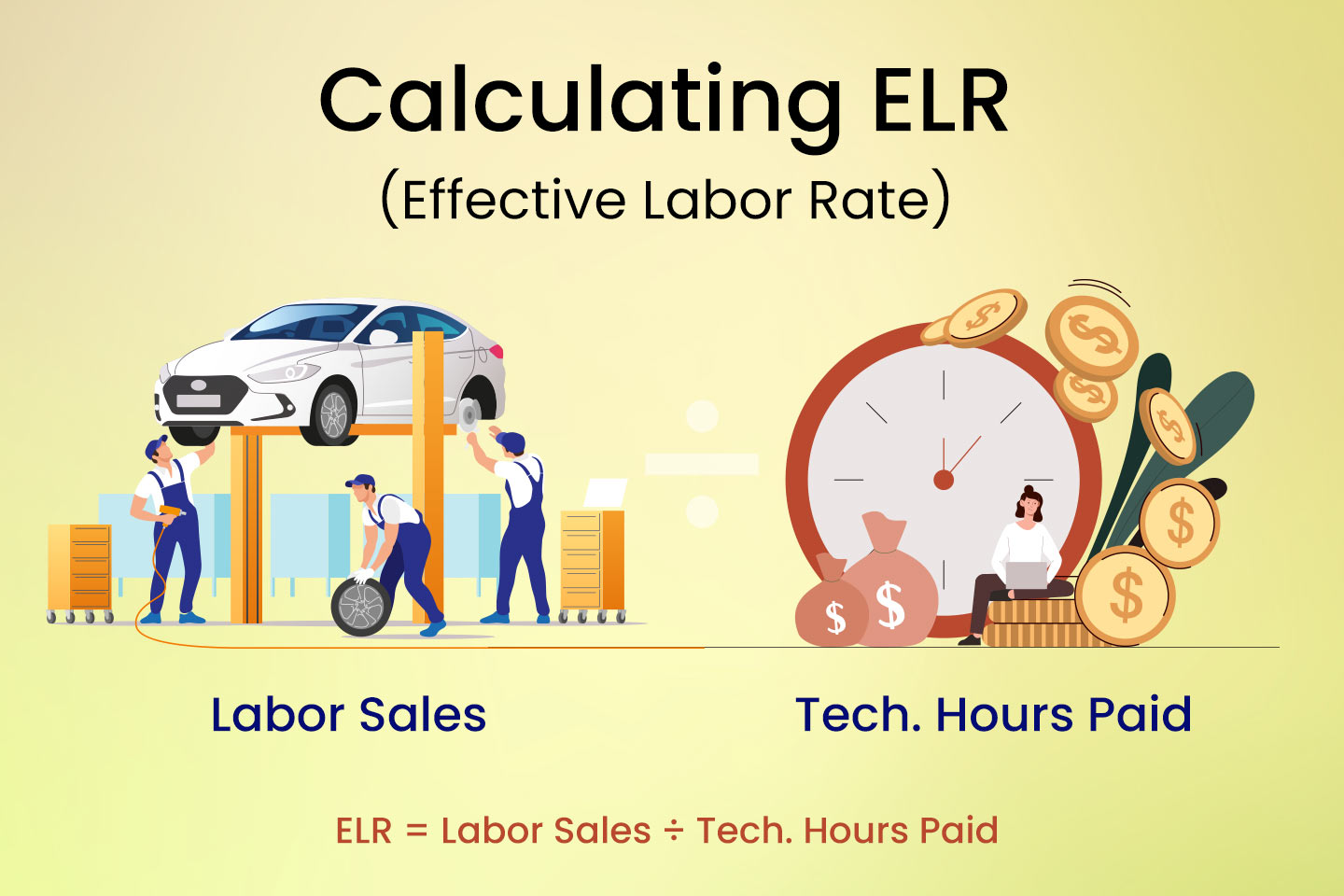

The first step is understanding how ELR is calculated: labor sales divided by tech. hours paid. This can be broken down by customer pay, warranty, and internal work. To influence ELR, you must change either the labor dollars sold per hour or the tech. hours paid per hour—a delicate topic when it comes to technicians. However, this shouldn’t be the first approach in most dealerships.

Start by assessing if repair orders are billed according to management policy. At 60-65% of dealerships, they aren’t. Often, service advisors control ELR. A quick test? Mystery shop your store. Are prices consistent across employees? Run simple reports to check your work mix. If your actual door rate isn’t charged as often as your repair labor operations are used, your ELR is being manipulated. Advisors typically aren’t to blame—they likely haven’t received clear management guidelines.

Regaining Control of ELR

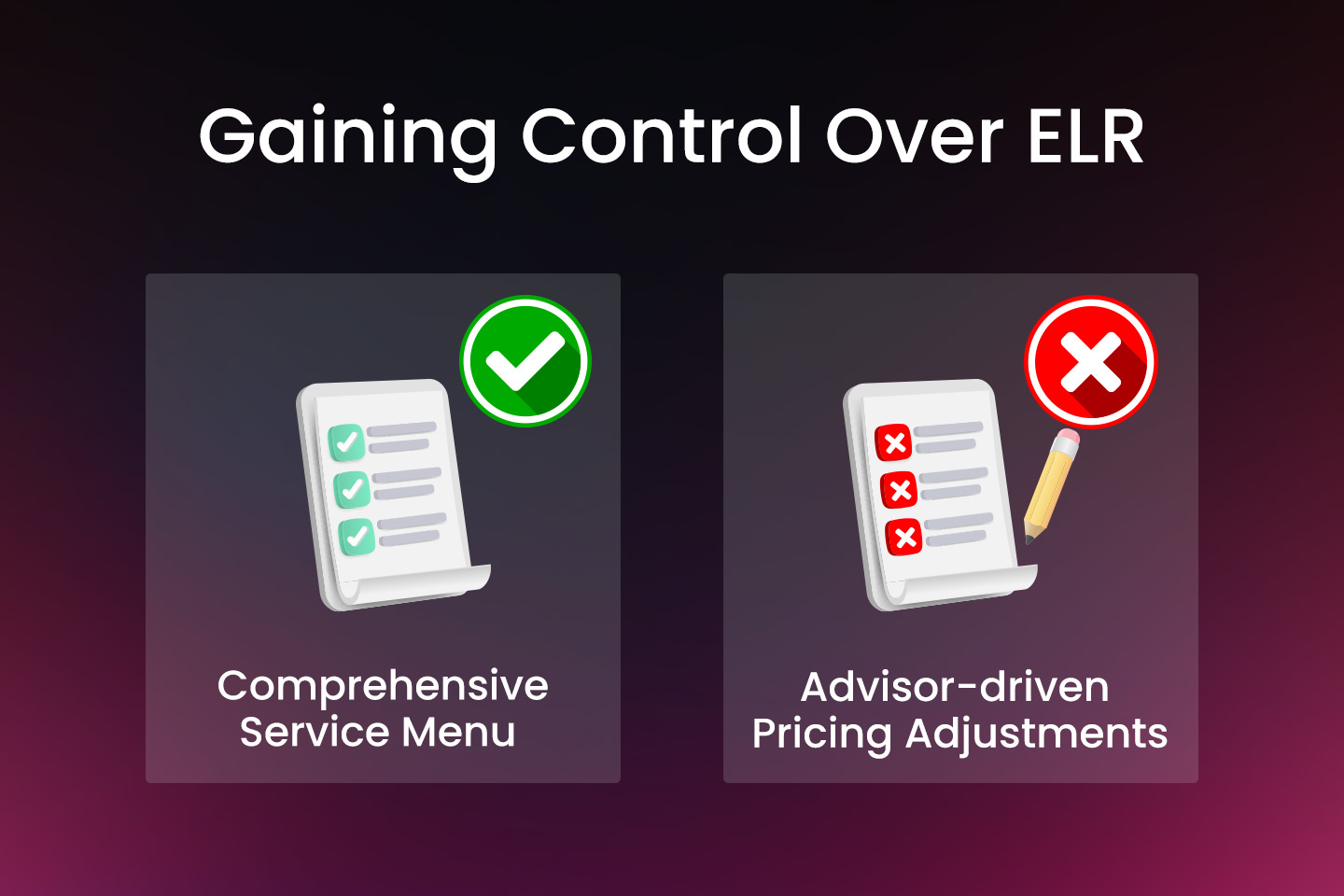

People naturally choose the path of least resistance. If price manipulation is allowed once, it’s likely to continue. In an average dealership, only two variables should affect ELR: management’s pricing model and the work mix. The more repairs billed at the door rate, the higher your ELR. By eliminating the variability introduced by advisor-driven pricing adjustments, management regains control over ELR and pricing. A seemingly small difference, like $4 per hour on one repair order, can translate into tens of thousands over time.

Advisors often argue they need pricing flexibility. In reality, they don’t. Fleet customers and extended warranties should have assigned labor types, and discounts should be managed as such—not as price changes. Labor types and discounts can be easily monitored and controlled.

Implementing a comprehensive menu that covers 90% of maintenance, combined with a policy that non-menu items are billed at Door Rate X Tech. Time, can resolve many ELR issues. Even managers who understand ELR and profitability and can program the DMS often lack the time to focus on it fully. Service managers are busy troubleshooting tech. issues, resolving disputes, running reports, and handling customer concerns, leaving little bandwidth for fine-tuning ELR structure.

To succeed, service departments need the right support, at the right time—now.

If you are looking to streamline your FixedOps strategy, reach out to us at sales@frogdata.com and let’s discuss how to make your FixedOps profitable.